Showing 13–24 of 80 results

-

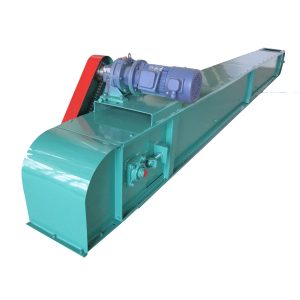

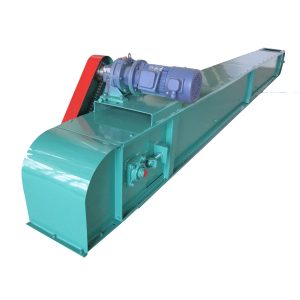

Features for Closed belt conveyor 1.It is used for conveying all kinds of bulk materials, it is also used for all kinds of cardboard boxes, bags and other single pieces of small pieces of goods. 2.It is based on the principle of rolling friction, there is almost no resistance in the conveying process. 3.Advanced technology, reasonable structure, low…

-

Features of Column Pellet Palletizer 1.High efficiency, stacking capacity: 400-500 bags/hour 2.High operating precision, large working range, small footprint, flexible action. 3.The stacking type and the number of stacking layers can be set arbitrarily, and the stacking type is neat and convenient for storage and transportation. 4.The number of palletizerlayers :1~12 layers. 5.Stacking on both…

-

Features 1.Materials are feed from the top to the bottom, and the cold air is from the bottom, which realizes effective and fully cooling. 2.Adopt counter flow cooling principle, more sufficient and effective cooling. 3.Adopt sliding product discharging mechanism, stable running, reliable &mooth. 4.The temperature of pellet after cooling is less than ambient +3-+5℃. 5.Automatically stop…

-

Features for double rotor hammer mill 1.Unique dual rotor structure combine with a unique patented technology, improving the efficiency of crushing. 2.Use curved strip type press screening mechanism and is more convenient to replace screen. 3.The guide mechanism adopts the handle locking type, change the feeding direction of simple and reliable. 4.The rotor adopts dynamic balance to ensure…

-

1. For fish feed, shrimp and crab aquatic feed conditioner.

2.The use of axial into the steam, greatly improves the aging effect and ensure the high-quality particle.

3. Optional intelligent automatic control system, high efficiency, data can be monitored.

4.Made of stainless steel food grade material, very safe and healthy.

-

Yongli floating fish feed extruder machine is application for Catfish,tilapia, shrimps, gold-fish, tropical fish,dog,cat,bird,etc.

Floating fish feed extruder machine is a kind of fish feed pellet machinery ,it is suitable for small and medium feed process factory and aquaculture farm. It can produce high-grade feed pellets which is suitable variety aquatic ,such as fish, catfish, crab, shrimps,cat,dog etc.All of our feed extruder are produced with twin screw extruder. Welcome to inquiry us anytime.

-

- 1.Micro liquid spraying,suitable for enzyme,fat,oil continuous spraying.

- 2.The feed quantity is adjustable.

- 3.Parts contacting with the material are made of stainless steel.

- 4.Weighing,atomizing nozzle,accurate spraying.

-

- 1.The machine use drum to keep the material moving,high-pressure spraying nozzle sprays liquid and full contact with the surface of feed,to ensure uniform spraying.

- 2.Widely applicable in spraying grease,molasses,enzymes, vitamins,organic acids and other nutrients and drugs on the surface of pellets and extruded feed,especially applicable for the production of high energy feed.

- 3.Additive amount is controlled by the system,quantity of liquid addition is 1%-8%.

- 4.Achievement of automatic combination for spraying is possible according to the additive amount.

- 5.Spraying proportion:3%~8%.

- 6.Rotation speed of drum:7-8rpm

-

Features of FADM Series Feed additive Adding Machine 1.Stainless steel production. 2.Including 6 cylinder dust collector and fan.

-

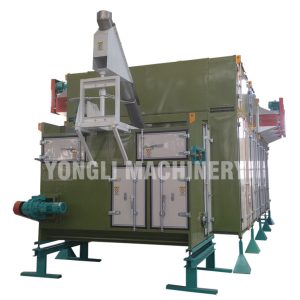

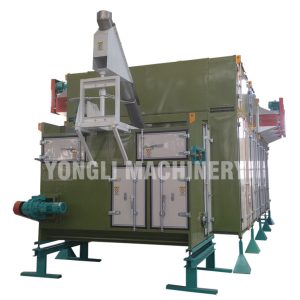

Features of feed dryer An effective solution to curing and drying problems of expanded aquatic feed,general particle feed and food. Making the particles achieve desired water resistance and improve the appearance and output of particles. Mesh with high-molecular polymer screen mesh or stainless steel stencil, perforated plate, non-stick material, clean and sanitary. Unique air duct system, built-in circulation…

-

Feed hammer mill is application for hammer mill feed grinder, fish feed grinder, etc.

-

Features for feed pellet cooler 1.Materials are feed from the top to the bottom, and the cold air is from the bottom, which realizes effective and fully cooling. 2.Adopt counter flow cooling principle, more sufficient and effective cooling. 3.Adopt sliding product discharging mechanism, stable running, reliable &mooth. 4.The temperature of pellet after cooling is less than…