Showing 61–72 of 80 results

-

- 1.Direct connect by special air bag and solenoid valve to ensure the less damage to the solenoid valve diaphragm and the stable and reliable running.

- 2.High-tech and famous product, original structure, compact craftsmanship.

- 3.Double inlet, flexible layout, small covered area.

- 4.High efficiency dedusting(≥99.9%).

- 5.The choice of bag can be ultra-fine, temperature resistance, humidity resistance, antistatic depends on user needs.

- 6.Mainly used for charging pot, requirement of negative pressure and less dedusting volume place.Small size is the feature of this kind of pulse filter.

- 7.Advanced technology, reasonable structure, low running noise

- 8.Large door structure, easy to maintain and replace filter bags.

- 9.Adopt advanced pulse control system, greatly improve the efficiency ofdust, extend the bag lifetime.

-

- It is a special equipment which can broke the large particles into small particles.

- It can crumble various pellets into 0.6-1.5 mm or 1-2.5 mm particles.

- Compact structure,double-roll structure, broken evenly, particle size adjustable convenient and quick.

- Roller uses differential rotational speed, the materials by extrusion, shear, tear effect between two rolls , so as to achieve the desired crushing effect.

- The unique feeding hopper and the bypass device not only have the function of refining material, but also the side flow of the material which does not need to be broken.

- Automatic shutdown by stroke switch when side flow.

- The roll shrimp feed can be customized.

- It is with feeding roll and by pass for convenient operation when side flow.

-

As a leading manufacturer of steel silo project,YONGLl is particularly focused on the quality of the silo!We are continuous researching and developing new technology to improve production technology and manufacturing level.

-

Features of super micro hammer mill Patented hammer structure, the output increased by 30%. Apply appropriate aerodynamics to design the screening and dischargingimprove the passage rate of materials , the sieve rate of 80 mesh is 95%. Spare parts using high-strength&wear-resistant material, Life expectancyincreased by 20%. Applicable for various types of raw materials, such as:…

-

-2-300x300.jpg)

- This pulse filter direct connect by special air bag and solenoid valve to ensure the less damage to the solenoid valve diaphragm and the stable and reliable running.

- High-tech and famous product, original structure, compact craftsmanship.

- Double inlet, flexible layout, small covered area.

- High efficiency dedusting(≥99.9%).

- The choice of bag can be ultra-fine, temperature resistance, humidity resistance, antistatic depends on user needs.

- Mainly used for charging pot, requirement of negative pressure and less dedusting volume place.Small size is the feature of this kind of pulse filter.

- Advanced technology, reasonable structure, low running noise

- Large door structure, easy to maintain and replace filter bags.

- Adopt advanced pulse control system, greatly improve the efficiency ofdust, extend the bag lifetime.

-

- Tubular Magnet is mainly used to separate the magneticmetal impurities in the raw materials.

- Iron removal efficiency≥99%

-

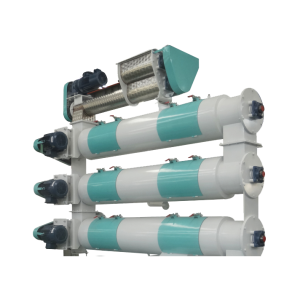

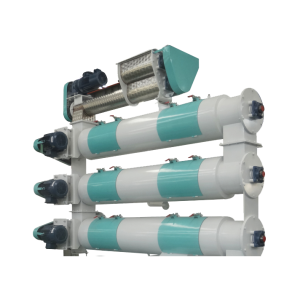

Features for Three Layers Feed Conditioner It is widely used for shrimp,crab feed pelleting.

-

-2-1-300x300.jpg)

- It is a special equipment which can broke the large particles into small particles.

- It can crumble various pellets into 0.6-1.5 mm or 1-2.5 mm particles.

- Compact structure,double-roll structure, broken evenly, particle size adjustable convenient and quick.

- Roller uses differential rotational speed, the materials by extrusion, shear, tear effect between two rolls , so as to achieve the desired crushing effect.

- The unique feeding hopper and the bypass device not only have the function of refining material, but also the side flow of the material which does not need to be broken.

- Automatic shutdown by stroke switch when side flow.

- The roll shrimp feed can be customized.

- It is with feeding roll and by pass for convenient operation when side flow.

-

- 1.Long time hot steaming,materials fully gelatinized,easy to press molding.

- 2.Long time heat preservation,advance the water resistance of particles,improve the surface and internal quality of particles.

- 3.Improve the digestion and absorption rate of feed after quality preservation,and eliminate harmful factors to a greater extent.

- 4.Improve the capacity of pellet machine and extruder machine.

- 5.All non-embroidered steel production,jacket steam insulation.

-

YONGLI can supply high rank aqua feed extrudering turnkey projects for clients.The capacity of aqua feed extruder line is 1t/h, 2t/h, 3t/h, 4t/h, 5-6t/h, 7-8t/h, 9-10t/h, 11-12t/h, etc. Granular size is normally 1-6mm.

YONGLI is one of the top feed mill manufacturers in the industry. With a global presence and a reputation for quality and innovation, YONGLI machinery is a trusted name in the feed industry. Our company offers a wide range of feed products for various species, including shrimp, fish, crab, cattle, poultry, and swine, etc.YONGLI’s feed mills are equipped with state-of-the-art technology to ensure the highest quality and consistency in their products. In addition to feed production, YONGLI also provides nutritional consulting services to help farmers optimize their feed programs for maximum efficiency and profitability.

-

Uniform coatingn and low breakage rate ensue the best pellets quality.

The new spiral rotor and discharge door structure minimizes breakage and residual rate.

With precise step-by-step vacuum release system, coating effect is controllable.

-

Features 1.Make use of the vibrating screen surface, it will classify the pellet according to different particle size. 2.Screening body’s driving mode is balanced vibration, that is, in screening of symmetry ship installation with two vibration motor driver sieve body, two motor to relative to offset the horizontal vibration force, vertical vibration force stack, ensure the normal body movement trajectory…

-2-300x300.jpg)

-2-1-300x300.jpg)