Premix Feed Production Line

As an important part of the modern feed industry, premixed feed has its unique process characteristics. First of all, the premix contains a variety of trace elements, and the proportion and amount of these trace elements in the feed have strict requirements. In order to ensure the accuracy of the proportioning, computer automatic batching systems are widely used in the production process of premixed feed. The application of this technology not only greatly improves the accuracy and efficiency of ingredients, but also reduces quality problems caused by human errors.

Premix Feed Production Line

YONGLI is familiar with the rules, requirements and standards for the production and application of premixes and applies them in the design, manufacture and installation of premix processing lines, we can ensure customers to process raw materials efficiently and add value.

As an important part of the modern feed industry, premixed feed has its unique process characteristics. First of all, the premix contains a variety of trace elements, and the proportion and amount of these trace elements in the feed have strict requirements. In order to ensure the accuracy of the proportioning, computer automatic batching systems are widely used in the production process of premixed feed. The application of this technology not only greatly improves the accuracy and efficiency of ingredients, but also reduces quality problems caused by human errors.

Premix Feed Production Line Implementation Of Each Process

Receiving And Storing Process

To ensure continuous production, a large kinds of raw materials nened to be stored during the feed processing to increase the storage stability of the raw materials and maintian the quality.

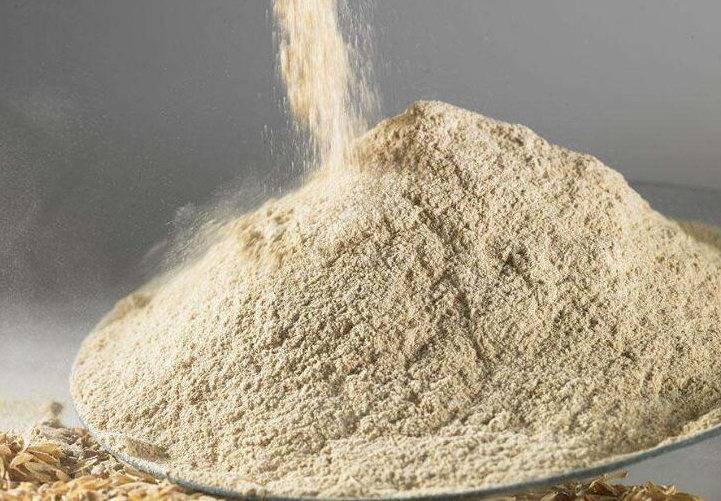

Grinding Process

Grinding is an operation that reduces the raw materials size of feed, which can enhance the digestion ability of animals. It can provide you with various particle size solutions for crushing the front and back ends, coarse and find powders.

Batching Process

The proportion of each ingredient can be determined, and the discharge machine is equipped with a variable frequency motor for variable frequency discharge, impromving the speed and accuracey of ingredients.

Mixing Process

The mixing process is used for mixing powdery, granular, flaky, lumpy and viscous materials in feed. It has high mixing uniformity, no dead ends in mixing, and a short mixing cycle. Each batch of materials can generally be mixed evenly within 30 to 120 seconds; the discharging adopts a bottom full-length door opening structure, which enables rapid discharge and low residual rate.

Bagging Process

It is the last process for the Ruminant Feed Line. According to your capacity request, you can chose semi-auto bagging machine, or automatic bagging machine. The fully automatic pellet bagging machine can realize automatic bagging, automatic detection, automatic measurement, automatic filling, automatic forming and automatic bag sewing.

The Pictures Of Premix Feed Production Line