Aqua Feeds Mill

YONGLI supply complete turnkey projects for aqua feeds pellet line, aqua floating fish feed line and silo storage. The aqua feed line capacity range from 1TPH to over 100TPH.

- Application: fish feed, shrimp and crab aquatic feed, livestock and poultry feed, forage feed, pre-mixed feed granulation.

- Equipped with double-layer conditioner, the use of axial into the steam, which greatly improves the aging effect and ensure the high-quality particles.

- All imported bearings and oil seals, longer service life.

- Siemens motors, SKF bearings.

- Screw and conditioner all made of stainless steel, food grade material, safe and healthy.

YONGLI supply complete turnkey projects for aqua feeds pellet line, aqua floating fish feed line and silo storage. The aqua feed line capacity range from 1TPH to over 100TPH.

Aqua feeds mill

Available raw materials: Corn, Brown rice, Paddy, Sorghum, Soybean and other feed formula materials etc.

Applicable feed pellets: aqua feed such as fish, shrimp, crab etc.

Feed Line Process: Including Receiving, Grinding, Mixing, Pelletizing, Cooling and Packing line.

Features For Aqua Feeds mill

- Double or triple conditioners can be cus-tomized for high rank aqua feed.

- Gear directly-connecting driving is adopted for high efficiency

- Full stainless steel feeder.

- Variable pitch and anti bridging structure.

- Electromagnetic converter control.

- Stainless steel conditioner;axial steam spraying extend the conditioning time and cooking effect.

- Main gear and pinion shaf adopt the carbonizing quenching with high accuracy;smooth driving,low noise, long service life.

- Gearbox and driving holes’accuracy are gu-aranteed by specialized casting supplier and NCC.

Technical Parameters for Aqua Feeds mill

Model | Capacity(t/h) | Power(kw) | Power of conditioner(kw) | Power of feeder(kw) | Inner Diameter of Die(mm) | Pellet Size(mm) |

YPM250 | 0.5-1.5 | 0.5-1.5 | 2.2×3 | 0.55 | φ250 | φ1-5 |

YPM320 | 2-3 | 37 | 2.2×3 | 0.75 | φ320 | φ1-5 |

YPM350 | 3-5 | 55 | 2.2×3 | 0.75 | φ350 | φ1-5 |

YPM420 | 3-5 | 110 | 5.5×3 | 1.5 | φ420 | φ1-5 |

YPM508 | 4-15 | 132/160 | 7.5×3 | 1.5 | φ508 | φ1-5 |

YPM600 | 6-21 | 185/200 | 11×3 | 1.5 | φ600 | φ1-5 |

YPM800 | 8-25 | 250/315 | 11×3 | 1.5 | φ800 | φ1-5 |

The advantage of YONGLI aqua feeds mill production line

- Over 26 yearsexperience in manufacturing and marketing feed mill projects.

- Full services forWorkshop design, Machine production, Installation, Commissioning and Operation training etc.

- Customized different capacities and equipment of poultry, animal, floating fishfeed line.

- The feed line capacity can range from 1t/h to over 100t/h.

- The service life of the production line is over 15 years.

- Touch screencomputer control system, which can realize the automatic control equipment operation and monitor equipment operation data, enabling a key to start- stop.

The process for aqua feeds mill production line

1.Receiving section: All kinds of raw materials into the appropriate bins, with good and pulverized into feed hammer mill.

2.Grinding section: By changing the crusher screen mesh, to get different grinding fineness of materials, to facilitate the needs of different growth stages of feed pellet production.

3.Mixing section: Mixer has high mixing evenness, fast discharge and low residue.

4.Pelleting ,cooling and screening section: For high temperature steam modulation and strong compression, compressed into appropriate particle size, then process with cooling, crushing and screening.

5.Packing section: By automatic packing machine, packaged pellets into different specifications of the bags for storage or sales.

YONGLI aqua feeds mill project case

10T/H Aquatic feed pellet production line

30T/h aqua feeds mill and 5t/h floating fish feed extruder line

30T/H Aquatic feed and 5T/H Floating Fish Feed Production Line

30t/h aqua feed pellet line

5T/H Floating Fish Feed And 3TPH Sinking Feed Line

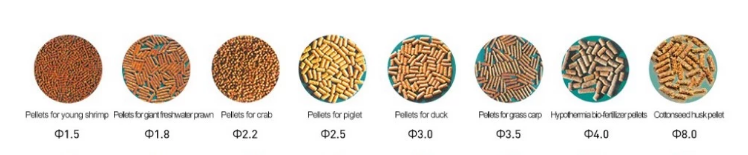

Finished pellets for aqua feeds mill

YONGLI not only provide the aqua feeds mill, aqua feed pellet line turnkey projects, but also provide the best service for our clients all over the world. Our service as below:

- Make optimal design and layout according to clients raw material and capacity request.

- Make booking for shipment from YONGLI factory to clients factory.

- Provide installation and debuggingfor clients.

- Provide free training on-site for clients.

- Provide Englishmanual for whole line machines to clients.

- Quarterly return visit to clients.

Spare parts for aqua feeds mill

FAQ

1. How can I trust on your quality?

1). All machines be tested successfully in Yongli workshop before shipment.

2). The working lifespan of Yongli machines is at least 20 working years.

3). Yongli wins totally 30 national patents for machines.

2.Does your company provide Engineers Abroad Service?

Sure, we provide it. And we can provide free training for on-site workers.

3.How to train our staff about operation and maintenance?

We will provide every detailed technical instructive, pictures, videos to teach them for the operation and maintenance. In addition, our engineers for guide assembly will teach your staff on site.

4.Where is your factory located? How can I visit there?

Our factory is located in Liyang City, Jiangsu Province, China, it is nearby Shanghai. You can fly to Shanghai airport or Nanjing Airport directly. Our driver to pick you up at the airport or train station etc.

Welcome to contact us! Welcome to visit our factory!

We will provide you the best equipments with the reasonable price to meet your requirements.

If you need any further information, do not hesitate to contact us !

Video for aqua feeds mill turnkey project