When it comes to purchasing a feed granulator machine, there are several factors that can affect the price. Understanding these factors is crucial for making an informed decision and getting the best value for your money. In this article, we will explore the key factors that influence the price of a feed granulator machine.

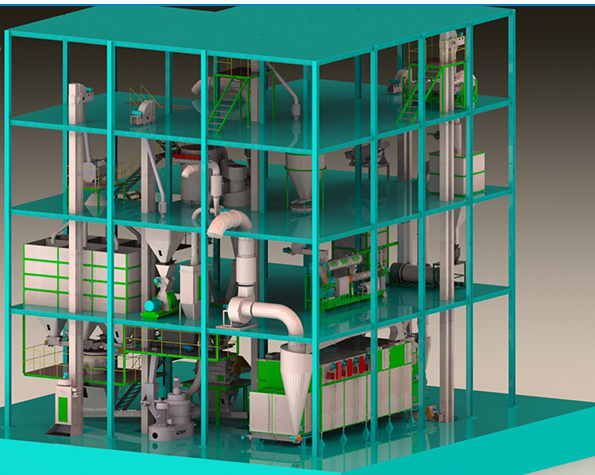

Firstly, the capacity of the machine plays a significant role in determining its price. Feed granulator machines come in various sizes, with different production capacities. Machines with higher capacities are generally more expensive than those with lower capacities. This is because larger machines require more materials and components, which increases their manufacturing cost. Another factor that affects the price of a feed granulator machine is the quality of its construction. Machines made from high-quality materials and components tend to be more expensive than those made from lower-quality materials. This is because high-quality machines are more durable and have a longer lifespan, which makes them a better investment in the long run.

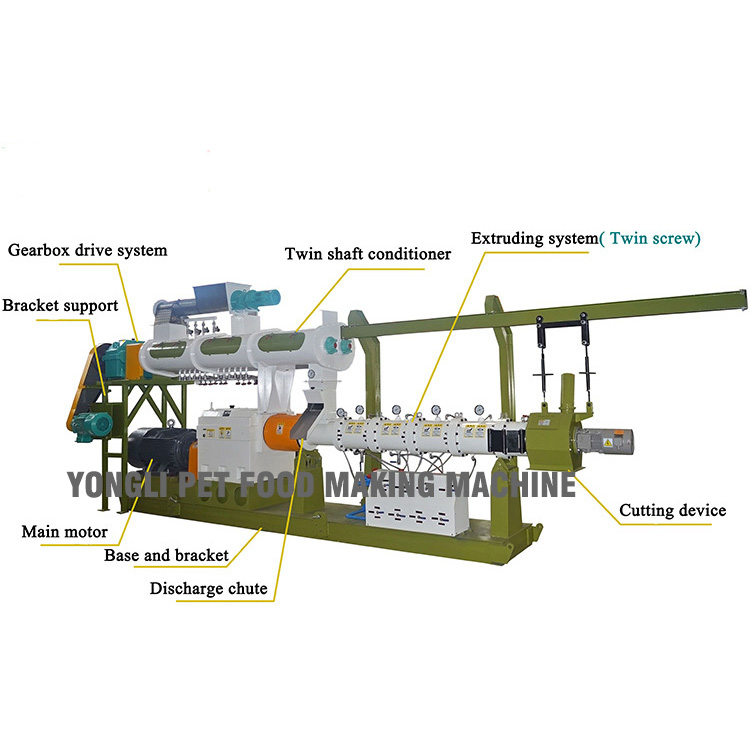

The technology used in the feed granulator machine also impacts its price. Machines that incorporate advanced technology and automation features are generally more expensive than those with basic functionalities. Advanced technology allows for greater efficiency and productivity, which can result in higher-quality feed pellets. However, it is important to consider whether the additional cost is justified based on your specific needs and production requirements.The brand reputation and customer support provided by the manufacturer can influence the price of a feed granulator machine. Well-established brands with a strong repation for producing reliable and high-performance machines often charge a premium for their products. This is because customers are willing to pay more for the assurance of quality and after-sales support. On the other hand, lesser-known brands may offer lower prices to attract customers, but they may not provide the same level of reliability and customer service.

Additionally, the availability and cost of spare parts and maintenance services should be considered when evaluating the price of a feed granulator machine. Machines that require specialized or hard-to-find spare parts can be more expensive to maintain and repair. It is important to choose a machine that has readily available spare parts and affordable maintenance services to avoid unexpected expenses in the future.