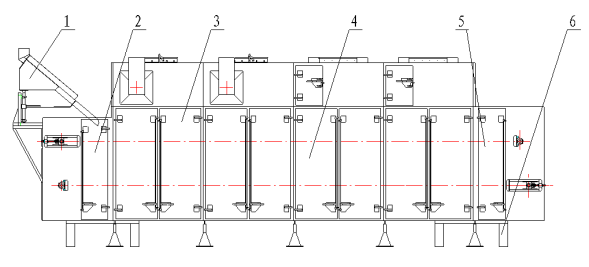

YHGJ Series Fish Feed Dryer Machine

YHGJ Series Fish Feed Dryer Machine

- An effective solution to curing and drying problems of expanded aquatic feed,general particle feed and food.

- Making the particles achieve desired water resistance and improve the appearance and output of particles.

- Mesh with high-molecular polymer screen mesh or stainless steel stencil.

Fish Feed Dryer machine features

- An effective solution to curing and drying problems of expanded aquatic feed,general particle feed and food.

- Making the particles achieve desired water resistance and improve the appearance and output of particles.

- Mesh with high-molecular polymer screen mesh or stainless steel stencil.

- Perforated plate, non-stick material, clean and sanitary.

- Unique air duct system, built-in circulation duct, can adjust the air flow direction according to the need.

- Double-layer material drying, effective use of space, improve productivity,

- Internal circulation hot air system, low energy consumption, low cost, good reliability.

Technical Parameters for Fish Feed Dryer machine

Model | YHGJ240x2-2 | YHGJ240x2-3 | YHGJ240x2-4 | YHGJ240x2-5 | YHGJ240x2-6 |

Power(kw) | 20.5 | 28.5 | 36.5 | 44.5 | 52.5 |

Capacity(t/h) | 3-4 | 4-5 | 5-6 | 6-7 | 7-8 |

Number of drying sections | 2 | 3 | 4 | 5 | 6 |

Main structure and working principle for Fish Feed Dryer machine

The drying treatment section of YHGJ Series horizontal dryer shall be provided by the dryer, heat source supply system,Ventilation and air flow control system, dust removal system, electrical control system, etc.

Main structure

The machine is mainly composed of machine base, feeding section, dry section, return section, crawler, swing feeder&other parts.

Swing Feeder

The part is driven by the connecting rod driven by the chain, and the discharging end of the feeder is oscillated reciprocally.Slip pipe feed port .Position does not move, achieves the uniform cloth effect.

Feed section

The feeding section is shaped steel frame, inner and outer wall board, with thermal insulation rock wool in the middle.The feeding section is provided with a crawler master.

Shaft bearing.Access door is convenient for users to repair and maintain the equipment.

Drying section

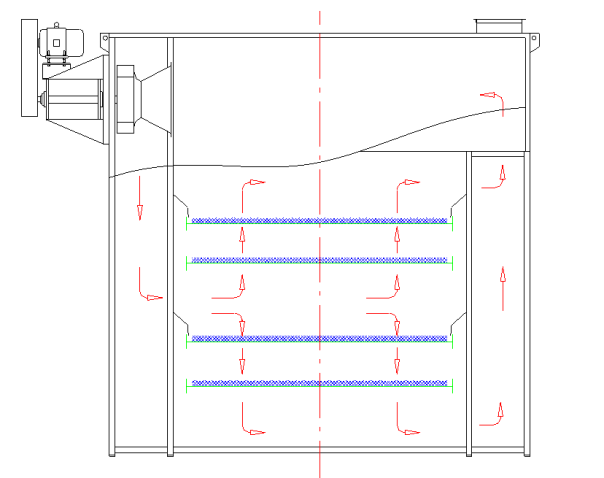

It is composed of upper and lower sections, steel frame, inner and outer wallboard, and insulation rock wool in the middle.Of each dry segment. The air duct forms a separate and complete circulation loop, with all the air ducts and ducts for circulation built in.In the A circulating fan and a heat exchanger are set in the section.

The drying time of the material here can be adjusted by the frequency conversion speed regulating motor, and the processing range of the equipment. For different materials and different requirements, can obtain the best drying effect.There are inner and outer doors on both sides to facilitate cleaning, maintenance and cooling after the dryer is shut down.

Track

The crawler belt is composed of conveyor chain, punching plate, baffle plate and sweeper. For lower sweeper.

To clean up the powder and debris inside the box.

Return section

It is a steel frame, inner and outer wall panels, and heat insulation rock wool in the middle. Crawler spindle support is also provided in the return section.

Base

The base is composed of several feet that can be adjusted in height independently, and has different installation planes,features such as firm support and strong bearing capacity.

Working principle for Fish Feed Dryer machine

This machine is a crawler dryer. The air heated by hot air is used as the drying medium. The flow-through drying method is used The hot air exchanges heat with the material to take away the moisture in the material and make it reach Moisture requirements for products. After the heat and moisture are exchanged between the drying medium and the materials on the crawler, part of the air is discharged out of the machine through the air outlet pipe, and the other part of the air is reheated by the heat exchanger, and the incoming fresh air enters the dryer again. The material is evenly spread on the crawler through the swing feeder, and enters the dryer along with the crawler. After the primary drying, it turns back in the feed section and enters the lower crawler for secondary drying and then discharges. Powder and scrap are discharged through the cleaning system.

Video