High Output 10t/h Twin Screw Extruder

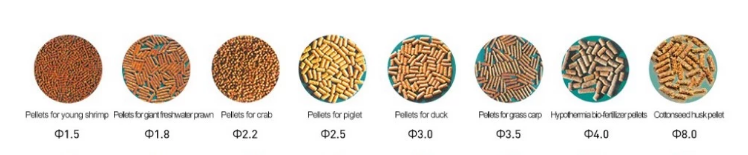

- YONGLI’s twin-screw extruder includes pet food extruders, aqua feed extruder, floating fish feed extruder, which can be used in aquatic feed production, such as fish, shrimp and crab feed food, as well as river eel, high-end ornamental fish feed, etc., used as floating fish feed extruder, shrimp feed extruder, etc. It can also be used for processing livestock and poultry feed, as animal feed extruder.

Twin Screw Extruder

- With the expansion of the application field of twin screw extruder machine, twin screw extruder have been widely used in the production of special feeds such as pet feed, aquatic feed and special economic animal feed, etc.

- YONGLI mainly designs and produces extruders and expanders in pet food aquatic and livestock feeds fields.

- According to our kinds of clients requirment, YONGLI has developed and manufactured a new type of twin screw food extruder with high performance, high reliability and high return, which is specially designed for the high-end feed processing market.

- This series of twin screw extruder has coverd more types of products, improved user experience and created greater value for users. We are engaged in the R&D and manufacturing of twin screw extruder machine and twin screw extrusion line projects, providing technical solutions and supporting products.

- YONGLI has exported twin screw extruder for sale Russia,Tunisia, Algeria, Egypt, Nigeria, Malaysia, Vietnam, Korea, Thailand, Indonesia, Sri Lanka, Dubai, etc. We promise that our customers can get optimum benefit at minimum risk.

- YONGLI’s twin-screw extruder includes pet food extruders, aqua feed extruder, floating fish feed extruder, which can be used in aquatic feed production, such as fish, shrimp and crab feed food, as well as river eel, high-end ornamental fish feed, etc., used as floating fish feed extruder, shrimp feed extruder, etc. We can also call it pet food mill. It can also be used for processing livestock and poultry feed, as animal feed extruder.

Features Of Twin Screw Extruder

- Using frequency control feeding, feeding evenly.

- Host gear box with oil pump cooling system and lubrication system.

- Screw extrusion pumping institutions and optional dual-axis lengthening differential modulator to make the material fully mature, The degree of gelatinization can reach more than 98%.

- Applicable to a wide range of raw materials, high fat content. Such diverse components as grains, soybean meal, animal meal, fresh meat, fats, nutrients, proteins, vitamins, starches and wet fish residue can be easily processed.

- The discharging cutter frequency control, easy to adjust the length of the material.

- Screw and screw barrel are all made of special materials, wear resistance, bear greater pressure.

- Killing germs by high temperature and high pressure during the process to ensure the safety and health of feed products.

Spare parts for twin screw extruder

With the rapid development of the feed industry, twin-screw extrder is widely used. The use of double screw extruder to produce high-quality, low-consumption aquatic, pet and livestock feed has become the goal pursued by many feed manufacturers. And the spare parts of the twin screw extruder is important and essential in the feed extruder production line. The following pictures are the spare parts for your review.

Technical Parameters Of twin screw extruder

Mode | Capacity(t/h) | Power(kw) |

SPHS75*2 | 0.5~0.8 | 37/45 |

SPHS90*2 | 1~2 | 55/75/90 |

SPHS100*2 | 2~3 | 110/132 |

SPHS126*2 | 4~6 | 160/200 |

SPHS180*2 | 8~10 | 250/355 |

twin screw extruder projects cases

30T/H Aquatic feed and 5T/H Floating Fish Feed Production Line

Video for twin screw extruder production line