Showing 13–17 of 17 results

-

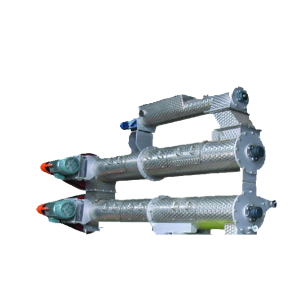

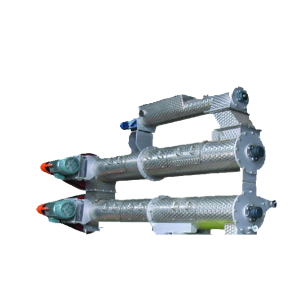

- 1.Long time hot steaming,materials fully gelatinized,easy to press molding.

- 2.Long time heat preservation,advance the water resistance of particles,improve the surface and internal quality of particles.

- 3.Improve the digestion and absorption rate of feed after quality preservation,and eliminate harmful factors to a greater extent.

- 4.Improve the capacity of pellet machine and extruder machine.

- 5.All non-embroidered steel production,jacket steam insulation.

-

Features for Double layers conditioner It is widely used for fish feed pelleting. Application For Double Layers Feed Conditioner 1. For fish feed, shrimp and crab aquatic feed conditioner. 2.The use of axial into the steam, greatly improves the aging effect and ensure the high-quality particle. 3. Optional intelligent automatic control system, high efficiency, data…

-

Fish feed mill, we also call it fish feed machine, fish feed pelletizer, fish feed granulator, etc.

The capacity of the fish feed mill is customized per client’s request, it is ranged from 1t/h to 50t/h, etc.

-

The Animal Feed Pellet Making Machine is the main machine in the feed pellet production line.

Except it, it also including the feed crusher, feed mixer, feed dryer, cooler, screener, pulse filter, tubular magent, pre-cleaner, bucket elevators, computer control system, packing machine, conveyors, storage silos etc.

-

YONGLI is a feed machine supplier from China. We are a real manufacturer, not middleman. We can provide all kinds of complete sets of feed machinery and solutions for feed mills and farms of all capacities, and have successfully exported to Portugal, Greece, Russia, France, Belgium, Hungary, Ukraine, Croatia, Romania, Tunisia, Algeria, Egypt, Nigeria, Malaysia, Vietnam, Korea, Thailand, Indonesia, Japan, Sri Lanka, Dubai, Australia, New Zealand, etc, totally over 5000+ clients.