-

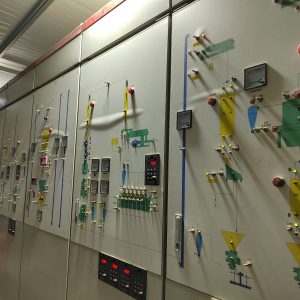

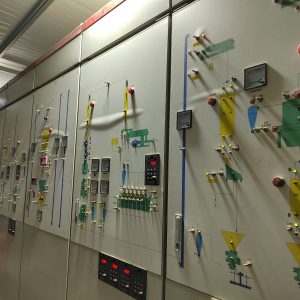

- Monitoring system is optional for key production procedure and supervisor can monitor all equipments freely.

- It can minimize contrived disturb and loss to increase efficiency.

-

- 1.Micro liquid spraying,suitable for enzyme,fat,oil continuous spraying.

- 2.The feed quantity is adjustable.

- 3.Parts contacting with the material are made of stainless steel.

- 4.Weighing,atomizing nozzle,accurate spraying.

-

- 1.The machine use drum to keep the material moving,high-pressure spraying nozzle sprays liquid and full contact with the surface of feed,to ensure uniform spraying.

- 2.Widely applicable in spraying grease,molasses,enzymes, vitamins,organic acids and other nutrients and drugs on the surface of pellets and extruded feed,especially applicable for the production of high energy feed.

- 3.Additive amount is controlled by the system,quantity of liquid addition is 1%-8%.

- 4.Achievement of automatic combination for spraying is possible according to the additive amount.

- 5.Spraying proportion:3%~8%.

- 6.Rotation speed of drum:7-8rpm

-

Model:SYTV32, SYTV63, SYTV128

-

Uniform coatingn and low breakage rate ensue the best pellets quality.

The new spiral rotor and discharge door structure minimizes breakage and residual rate.

With precise step-by-step vacuum release system, coating effect is controllable.