YHM Series Fish Feed Hammer Mill

Applicable for raw materials grinding for fish feed mill plant,food plant,solvent plant, alcohol plant, citric acid plant, oil plant, brewing plant,flour plant with different capacities.

Application scope

Applicable for raw materials grinding for fish feed mill plant,food plant,solvent plant, alcohol plant, citric acid plant, oil plant, brewing plant,flour plant with different capacities.

Features of fish feed hammer mill

- 1.The shell is welded by steel plate,the site in the crush room which connects to the materials all use the wearable and commutative parts and double wear plate.

- 2.Coarse and fine powder can both be achieved by adjusting the gaps between hammer and the screen by changing the location of the pin rod.

- 3.The motor and rotor are installed in the same heavy-duty base,using coupling direct drive,the rotor are checked by dynamic balance,and can work forward and reverse,the hammers are arranged symmetrically.

- 4.The second grinding for grinding chamber,the output can increase 15%even particle size.

Fish feed hammer mill working principle

- The material to be crushed is fed from the top feed port through the feeding mechanism matched with this machine, and enters the crushing chamber from the left or right through the feeding guide plate.

- The material is struck by the high-speed rotating hammer and the friction of the sieve plate. It is gradually crushed.

- When the particle diameter of the crushed material is smaller than the sieve hole, it passes through the sieve hole under the action of centrifugal force and air flow and is discharged from the base outlet.

Technical Parameters For Fish Feed Hammer Mill

Model | Diameter of rotor(mm) | Width of grinding chamber(mm) | Main Shft speed(rpm) | Hammer linear speed(m/s) | Hammer qty for general smash(pcs) | Hammer qty for find grinding (pcs) | Capacity for normal crushed(screen dia. >φ2.0 (t/h) | Capacity for fine crushed(screen dia. <=φ2.0,<=40mesh (t/h) | Power(kw) |

YHM56*36 | 560 | 360 | 2950 | 86 | 20 | 40 | 1~3 | 0.5~1 | 22/30 |

YHM56*40 | 560 | 400 | 2950 | 86 | 24 | 48 | 2~4 | 0.8~2 | 30/37 |

YHM60*45 | 600 | 450 | 2965 | 94 | 48 | 80 | 4~6 | 1.5~4 | 45/55 |

VHM60*60 | 600 | 600 | 2970 | 94 | 64 | 88 | 5~8 | 3~5 | 75/90 |

YHM60*80 | 600 | 800 | 2970 | 94 | 64 | 110 | 6~12 | 4~6 | 90 |

YHM68*80 | 680 | 800 | 2975 | 107 | 88 | 88 | 6~18 | 5~10 | 110 |

YHM68*120 | 680 | 1200 | 2975 | 107 | 120 | 120 | 15~25 | 10~15 | 160 |

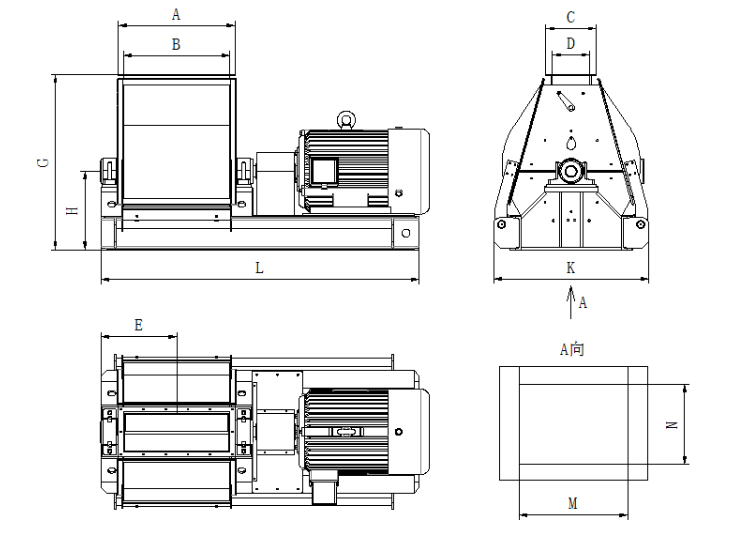

Prototype Drawing

Contact with YONGLI