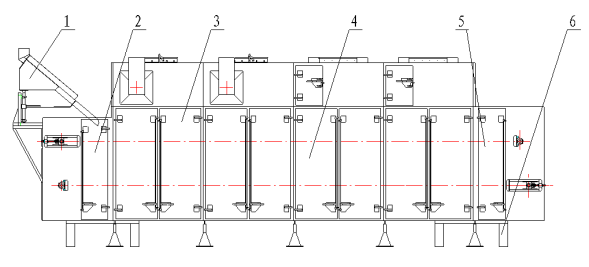

YHGJ240 Animal Feed Dryer

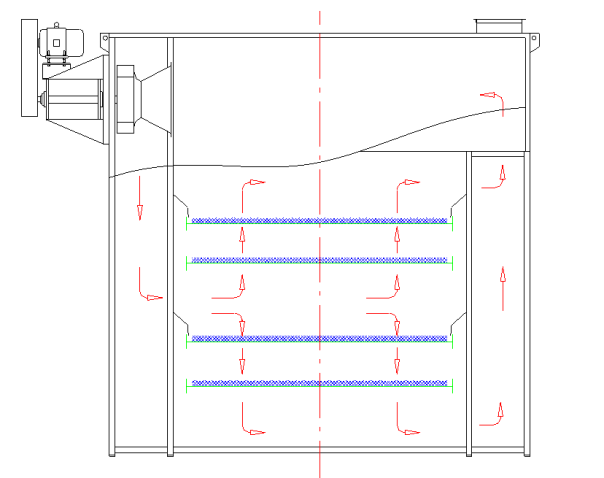

This machine YHGJ240 is a crawler dryer. The air heated by hot air is used as the drying medium. The flow-through drying method is used The hot air exchanges heat with the material to take away the moisture in the material and make it reach Moisture requirements for products. After the heat and moisture are exchanged between the drying medium and the materials on the crawler, part of the air is discharged out of the machine through the air outlet pipe, and the other part of the air is reheated by the heat exchanger, and the incoming fresh air enters the dryer again. The material is evenly spread on the crawler through the swing feeder, and enters the dryer along with the crawler. After the primary drying, it turns back in the feed section and enters the lower crawler for secondary drying and then discharges. Powder and scrap are discharged through the cleaning system.

features for YHGJ240 Animal Feed Dryer

- An effective solution to curing and drying problems of expanded aquatic feed,general particle feed and food.

- Making the particles achieve desired water resistance and improve the appearance and output of particles.

- Mesh with high-molecular polymer screen mesh or stainless steel stencil.

- Perforated plate, non-stick material, clean and sanitary.

- Unique air duct system, built-in circulation duct, can adjust the air flow direction according to the need.

- Double-layer material drying, effective use of space, improve productivity,

- Internal circulation hot air system, low energy consumption, low cost, good reliability.

Technical Parameters for YHGJ240 Animal Feed Dryer

Model | YHGJ240x2-2 | YHGJ240x2-3 | YHGJ240x2-4 | YHGJ240x2-5 | YHGJ240x2-6 |

Power(kw) | 20.5 | 28.5 | 36.5 | 44.5 | 52.5 |

Capacity(t/h) | 3-4 | 4-5 | 5-6 | 6-7 | 7-8 |

Number of drying sections | 2 | 3 | 4 | 5 | 6 |

Main structure and working principle for YHGJ240 Animal Feed Dryer

The drying treatment section of YHGJ Series horizontal dryer shall be provided by the dryer, heat source supply system,Ventilation and air flow control system, dust removal system, electrical control system, etc.

Main structure

The machine is mainly composed of machine base, feeding section, dry section, return section, crawler, swing feeder&other parts.

Working principle

This machine YHGJ240 is a crawler dryer. The air heated by hot air is used as the drying medium. The flow-through drying method is used The hot air exchanges heat with the material to take away the moisture in the material and make it reach Moisture requirements for products. After the heat and moisture are exchanged between the drying medium and the materials on the crawler, part of the air is discharged out of the machine through the air outlet pipe, and the other part of the air is reheated by the heat exchanger, and the incoming fresh air enters the dryer again. The material is evenly spread on the crawler through the swing feeder, and enters the dryer along with the crawler. After the primary drying, it turns back in the feed section and enters the lower crawler for secondary drying and then discharges. Powder and scrap are discharged through the cleaning system.

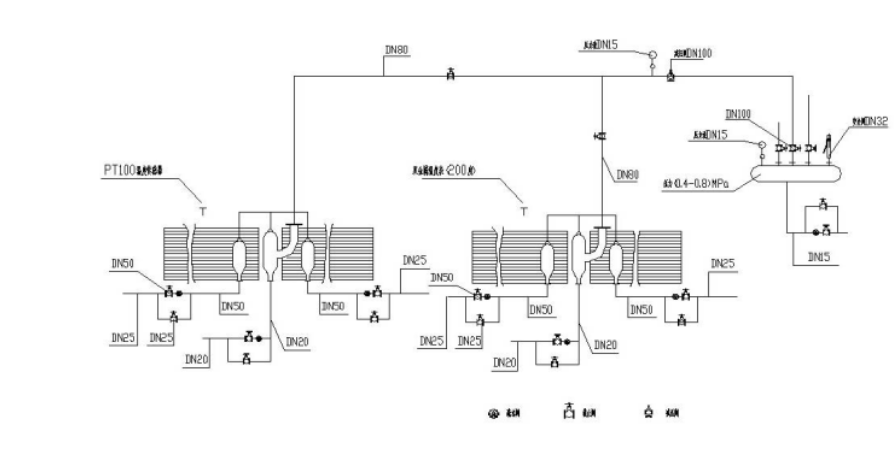

Heat source piping system

Heat source system diagram is a schematic diagram of steam as a heat source. The appropriate steam temperature will determine the drying effect of the dryer. The steam system of this machine is manually adjusted parameters.

Video