Automatic Pellet Packaging Machine System

The fully automatic pellet bagging machine is composed of an automatic packaging machine, a quantitative packaging machine, an automatic bag guide and a sewing machine assembly. It can realize automatic bagging, automatic detection, automatic measurement, automatic filling, automatic forming and automatic bag sewing. Quantitative packaging.

Automatic Pellet Packaging Machine System

The fully automatic pellet bagging machine is composed of an automatic packaging machine, a quantitative packaging machine, an automatic bag guide and a sewing machine assembly. It can realize automatic bagging, automatic detection, automatic measurement, automatic filling, automatic forming and automatic bag sewing. Quantitative packaging.

The difference between Semi-auto packaging machine and fully automatic packaging machine

Generally speaking, packaging machines refer to semi-automatic packaging machines, that is, manual bagging. After weighing, the materials fall into the packaging bags and are folded and sealed or directly sealed or heat-sealed. The characteristics of semi-automatic packaging machines are generally that the weighing is automatic. Yes, bagging is manual, so it is called a semi-automatic packaging machine.

Different from semi-automatic packaging machines, fully-automatic packaging machines are usually also called fully-automatic packaging machines or fully-automatic packaging scales. All processes are automatically completed by machines and equipment: automatic packaging bags are sorted, robots automatically load bags, and materials are automatically weighed. The process is automatically detected and corrected, materials are automatically filled into packaging bags, and packaging bags are automatically folded and sealed. The entire process is automatically controlled by PLC without manual participation.

The process of the fully automatic packaging machine

1. Automatic sorting of empty packaging bags: Due to irregularities in the production process and packaging and transportation process of purchased empty packaging bags, the mouth of newly purchased packaging bags is irregular, and the bags are bonded to each other. Packaging bag processing enterprises Instead of cold cutting, the hot cutting process will cause the bag mouth to stick together, making it difficult to open the bag with a vacuum suction cup, and the bag mouth needs to be processed by bag opening equipment. Newly purchased packaging bags can enter the next process well after being processed through the above processes. Requirements for packaging bags from fully automatic packaging machines: New packaging bags must be coated on at least one side. Packaging bags that are not coated on both sides cannot be used. Both double-layered packaging bags with inner film and coated packaging bags can be used normally. Generally, packaging requirements are required The weight of the bag is greater than 80 grams.

2. Packaging bag transfer (suction): Qualified empty packaging bags are sucked up by the vacuum suction cup. The lifting mechanism raises the bag to a certain height. The moving mechanism sends the bag to the bag opening position. The sorting mechanism is adjusted to the appropriate position through the packaging bag. , the bag mouth is opened by the bag opening process.

3. Opening the packaging bag: The vacuum suction cup presses the packaging bag from both upper and lower sides at the same time, and then moves from the upper and lower directions to suck the bag mouth open. Depending on the size of the packaging bag and the performance of the inner and outer bags of the packaging bag, the number and size of the bag opening suction cups must be determined through testing. The bagging process determines the success rate of bagging. Many bagging failures are due to failure in bagging, causing the bagging robot to fail to grasp, or the bag opening is not in place or the bag opening is irregular. Even if the bagging robot grasps successfully, The bags will not be standardized after bagging, which will eventually lead to irregular bag openings. The possible consequence is that the folding and sealing process fails, causing the packaging bags to leak.

4. Packaging bag loading: The bag loading robot developed by YONGLI has obtained a national invention patent. The patent of the bag loading robot (the working process of the bag loading robot) is described as follows: the bag taking mechanism includes a connecting arm. There are two upper opening arms and two lower opening arms hinged on the connecting arm respectively on the left and right. There is a telescopic mechanism hinged between the rear end and the rear end of the lower opening arm. An upper clamping arm is hinged on one side of the upper opening arm. The front end of the upper clamping arm corresponds to the front end of the upper opening arm. The rear end of the upper clamping arm corresponds to the upper opening. An upper clamping cylinder is hinged between the arms, a lower clamping arm is hinged on one side of the lower opening arm, the front end of the lower clamping arm corresponds to the front end of the lower opening arm, and there is a lower clamping arm hinged between the rear end of the lower clamping arm and the lower opening arm. Clamp cylinder. The telescopic mechanism is a single-cylinder double-arm cylinder, a single-cylinder single-arm cylinder or a connecting rod mechanism. The upper clamping arm is located outside or inside the upper opening arm, and the lower clamping arm is located outside or inside the lower opening arm. The utility model is used on an automatic bagging and packaging machine. During the bag taking and bagging processes, the size of the packaging bag mouth can be adjusted synchronously so that the bag mouth and the lower hopper are closely fitted, adapting to the needs of various material packaging, and the use effect is good. .

5. Filling of materials: After the empty packaging bag is put into the unloading port, the automatic detection device detects whether the packaging bag is in place. After confirming that the packaging bag is complete and in place, the qualified materials are weighed and placed into the packaging bag to complete the filling of the material.

6. Transfer, folding, and sealing of packaging bags: The filled packaging bags move forward through the conveyor. The whole bag mechanism organizes the mouth of the packaging bags, and then introduces it into the folding machine for folding and sealing to complete the material. Fully automatic packaging.

7. Control system of fully automatic packaging machine: The fully automatic packaging machine is controlled by PLC, and the touch screen performs data management and human-machine communication. For the entire fully automatic packaging machine, stable operation is the most important thing. High-quality accessories are the main factor in ensuring product quality.

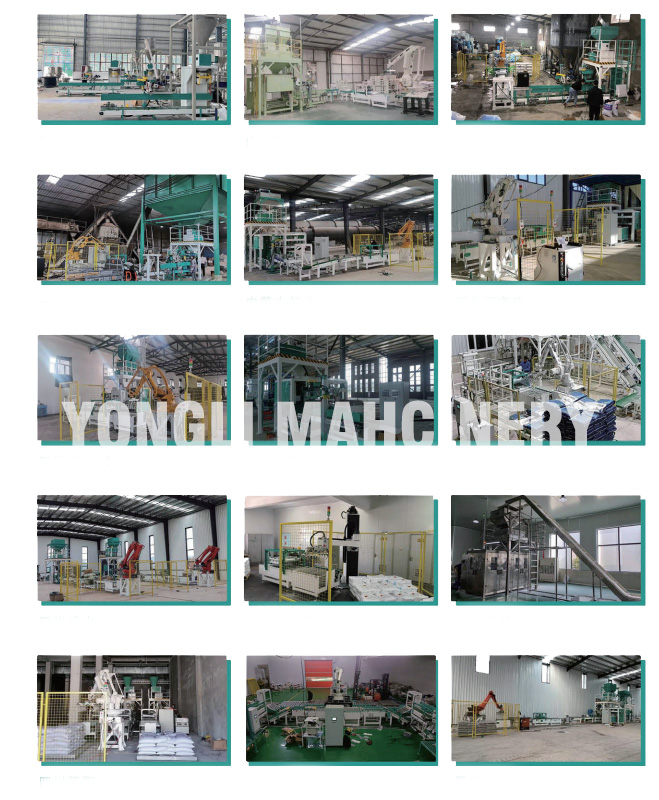

Project Cases

Fully automatic packaging machine features

1. The fully automatic packaging machine for woven bags can realize automatic sorting of packaging bags, automatic bag opening and absorption, automatic moving bag loading, fully automatic weighing and measuring, counting, filling, mobile output, and automatic bag folding and sewing into a fully automatic bag sewing machine. Achieve fully automated, digital and unmanned, environmentally friendly and low energy consumption throughout the packaging process.

2. The unit adopts touch screen control, making operation, specification switching and maintenance very convenient, safe and reliable. The whole set of equipment has a complete automatic detection program, automatic deviation correction, automatic fault detection prompts, and convenient maintenance. The operation of the equipment is personalized and does not require manual participation in the operation. Automatic fault alarms remind the operator of the fault location and phenomenon as well as fault detection and processing methods.

3. The fully automatic packaging machine can be used in any process production line that requires packaging bags to realize the automation of the material packaging process.

Technical parameters of fully automatic Pellet packaging machine

1. Fully automatic packaging machine packaging range: 20-50 kg bagged products;

2. Packaging materials: paper bags, woven bags (coated film), double-layer composite bags;

3. Packaging speed: 200-1200 packages/hour (packaging speed varies according to materials)

4. Packaging accuracy: 0.2%

5. Packaging materials: Depending on the materials, different feeding methods can be selected. It can pack granular materials, powder materials, flakes or mixed materials.

6. Compressed air: 0.4~0.8MPa, maximum air consumption 1.6 m3/min;

7. Power supply: 6.2Kw AC380V±10% 50Hz.

Video