Twin Screw Aqua Feed Extruder for fish, shrimp, crab

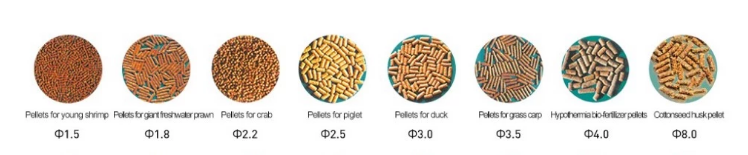

YONGLI can supply high rank aqua feed extrudering turnkey projects for clients.The capacity of aqua feed extruder line is 1t/h, 2t/h, 3t/h, 4t/h, 5-6t/h, 7-8t/h, 9-10t/h, 11-12t/h, etc. Granular size is normally 1-6mm.

YONGLI is one of the top feed mill manufacturers in the industry. With a global presence and a reputation for quality and innovation, YONGLI machinery is a trusted name in the feed industry. Our company offers a wide range of feed products for various species, including shrimp, fish, crab, cattle, poultry, and swine, etc.YONGLI’s feed mills are equipped with state-of-the-art technology to ensure the highest quality and consistency in their products. In addition to feed production, YONGLI also provides nutritional consulting services to help farmers optimize their feed programs for maximum efficiency and profitability.

Features for Twin Screw Aqua Feed Extruder for fish, shrimp, crab

- SPHS Series extruder is specialized for production of high rank floating,sinking aqua feed,aquarium fish feed,pet food,etc.

- Feeding System:special designed bin without subside materials ensures no bridging insid of bin and auto feeding system is available.

- SKF Bearing is adopted inside of driving box ensured stable driving and long service life.

- The cutter is with movable cutter base.The knife is made of spring steel and toothed with die plate well; FC inverter is used for control of cutter and the length of pellet can be adjusted.

- Using frequency control feeding, feeding evenly.

- Host gear box with oil pump cooling system and lubrication system.

- Double screw extrusion pumping institutions and optional dual-axis lengthening differential modulator to make the material fully mature,The degree of gelatinization can reach more than 98%.

- Applicable to a wide range of raw materials, high fat content.

- Double-screw structure with excellent self-cleaning ability to restart or replace the material varieties without cleaning machine boring and screw.

- The discharging cutter frequency control, easy to adjust the length of the material.

- Screw and screw barrel are all made of special materials, wear resistance, bear greater pressure.

- Killing germs by high temperature and high pressure during the process to ensure the safety and health of feed products.

Technical Parameters for twin screw aqua feed extruder

Mode | Capacity(t/h) | Power(kw) |

SPHS75*2 | 0.5~0.8 | 37/45 |

SPHS90*2 | 1~2 | 55/75/90 |

SPHS100*2 | 2~3 | 110/132 |

SPHS126*2 | 4~6 | 160/200 |

SPHS180*2 | 8~10 | 250/355 |

YONGLI can supply high rank aqua feed extrudering turnkey projects for clients.The capacity of aqua feed extruder line is 1t/h, 2t/h, 3t/h, 4t/h, 5-6t/h, 7-8t/h, 9-10t/h, 11-12t/h, etc. Granular size is normally 1-6mm.

The Picture Of twin screw aqua feed extruder

Spare Parts Of The twin screw aqua feed extruder

Granular From twin screw aqua feed extruder

YONGLI: YONGLI is an excellent provider and operator for pet food machine and feed production lines.

COOPERATION: We cooperate with over fifty countries clients and get high reputation by clients.

QUALITY: To ensure timely delivery of qualified products, we are fully involved in the production and quality control.

INNOVATION: To provide clients with better quality and high stable performance machine, we adhere to continuous innovation.

YONGLI is one of the top feed mill manufacturers in the industry. With a global presence and a reputation for quality and innovation, YONGLI machinery is a trusted name in the feed industry. Our company offers a wide range of feed products for various species, including shrimp, fish, crab, cattle, poultry, and swine, etc.YONGLI’s feed mills are equipped with state-of-the-art technology to ensure the highest quality and consistency in their products. In addition to feed production, YONGLI also provides nutritional consulting services to help farmers optimize their feed programs for maximum efficiency and profitability.

How To Make twin screw Aqua feed extruder Line For Clients

- 1.Grinding prcoess: By changing the crusher screen mesh, to get different grinding fineness of materials, to facilitate the needs of different growth stages of feed pellet production.

- 2.Batching and Mixing process: Various materials batching and enter into the mixer for fully mixing.

- 3.Extruding process and pelleting process: To use high quality twin screw extruder to pressure the corn etc into pellets.

- 4.Cooling process: The temperature of pellets is about 60-80 degrees. For storage purpose, a cooler must be used to reduce their surface temperature and moisture content.

- 5.Packing ProcessPacking process is to protect of the pellets becoming getting damp, and it is useful for transport and market sales.

- 6.Electric Control System: Control panel indicating processing flow; Can easily to fulfill automatic control of whole plant, such as start, stop and alarm as well as interlock function. We use Schneider electric components and soft starter, PLC control system.

Project Case For twin screw Aqua feed extruder

Video for Aqua feed extruder line

FAQ

1.Q: How can I trust on your quality?

Answer:

1). All of the machine be tested successfully in Yongli workshop before shipment.

2). The working lifespan of Yongli machines is at least 26 working years.

3). Yongli wins over 30 national patents for machines by our senior R&D engineers.

2. Q: What is your superiority comparing with other suppliers?

Answer:

1). Yongli can make optimal design based on your kinds of raw materials.

2). Yongli has overseas service center in Russia, Korea, Thailand, Malaysia, Tunisa, etc, which can provide you spare parts very fast and on-site service quickly.

3). Yongli R&D ability is very strong, it can develop 8-10 new technology every year.

4). It has at least 90% traders and distributors place order for Yongli every year.

3. Q: Does your company provide Engineers Abroad Service?

Answer: Sure, we provide it. And we can provide free training for on-site workers.

4. Q: How to train our staff about operation and maintenance?

Answer : We will provide every detailed technical instructive, pictures, videos to teach them for the operation and maintenance. In addition, our engineers for guide assembly will teach your staff on site.

5. Q:What shipment terms you offer?

Answer: We can offer FOB, CIF, CFR etc based on your request.

6. Q:What payment terms you take?

Answer: T/T, LC at sight etc.

7. Where is your factory located? How can I visit there?

Answer: Our factory is located in Liyang City, Jiangsu Province, China, it is nearby Shanghai. You can fly to Shanghai airport or Nanjing Airport directly. We can let our driver to pick you up at the airport or train station etc.