Vacuum Coater

Uniform coatingn and low breakage rate ensue the best pellets quality.

The new spiral rotor and discharge door structure minimizes breakage and residual rate.

With precise step-by-step vacuum release system, coating effect is controllable.

Features for vacuum coater

- 1.Tapered design reduces discharging time.

- 2.Fixed spraying,simple and safe, ensures the quality of particle coating.

- 3.Each spray system is equipped with 6 nozzles.

- 4.Spray 5 different liquids at the same time.

- 5.The nozzle can be changed quickly.

- 6.No leakage into and out butterfly valve.

- 7.Vacuum can be up to 80bar.

- 8.Built-in vertical screw hoist.

- 9.Up to 40%spray volume.

- 10.Discharge air compensation system.

- 11.The end of the feeding induced by the weight sensor.

Technical Parameter for Vacuum coater

Model | YZPT2 | YZPT3 | YZPT4 | YZPT5 |

Effective Volume(L) | 2000 | 3000 | 4000 | 5000 |

Capacity(t/h) | 4-8 | 6-12 | 12-15 | 15-20 |

Fat Addition | 1-36% | 1-36% | 1-36% | 3-36% |

Pellet Diameter(mm) | 1-30 | 1-30 | 1-30 | 1-30 |

Batch Time(min) | 5-7 | 5-7 | 5-7 | 5-7 |

Coating Uniformity | CV≤7% | CV≤7% | CV≤7% | CV≤7% |

Residue Rate | ≤0.5% | ≤0.5% | ≤0.5% | ≤0.5% |

Vacuum Retention | ≤100mbar/6min | ≤100mbar/6min | ≤100mbar/6min | ≤100mbar/6min |

Maximum Vacuum Degree | 40mbar | 40mbar | 40mbar | 40mbar |

Main Motor Power(kw) | 15 | 22 | 30 | 37 |

Vacumm Pump Power(kw) | 22 | 22 | 22 | 22 |

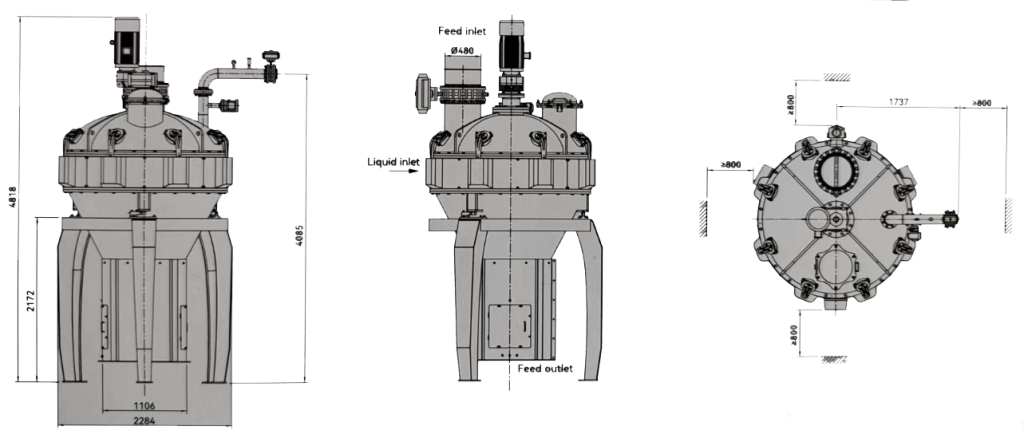

Prototype Drawing